-

Ship Geometry Survey

IMANTOSIS team, may provide Ship Geometry Surveys in any situation, both in dry docks and offshore. When every detail in high accuracy, is needed, point cloud generation is used to measure and illustrate any shape a contemporary or traditional vessel can form, from humble fishing boats to Carrier giants.

2D Technical or Naval Architectural and Maritime Engineering drawings, 3D registered solid point clouds and photorealistic models, can be considered amongst the most common derivatives. Deliverables, may be embedded in any CAD base software, the client favors, for future reference, repairs, damages and design comparison.

• Ship Exact Dimensioning

• Naval Blueprints Comparison

• Accurate Geometry Capture

• Future Reference

• Accurate Damage Definition

• Deformation inspection,

Twist, Straightness, Hogging -Sagging

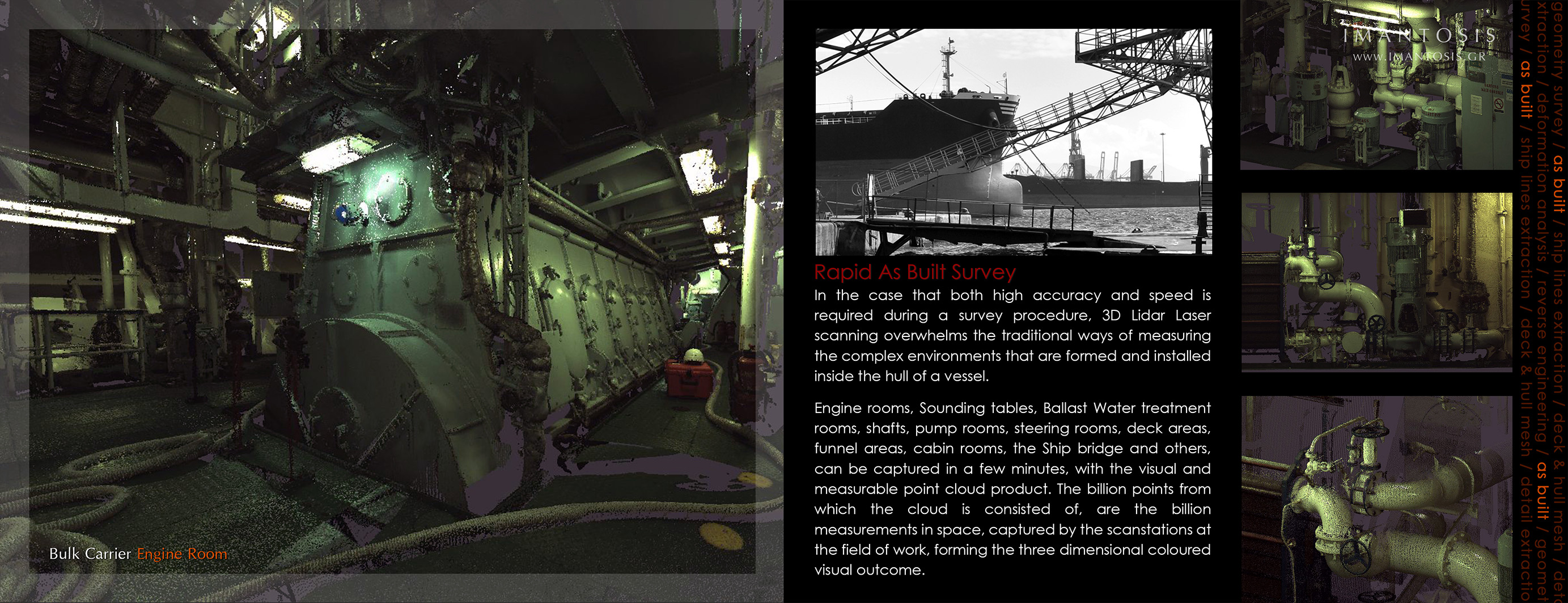

Rapid As Built Survey

In the case that both high accuracy and speed is required during a survey procedure, 3D LiDAR Laser scanning overwhelms the traditional ways of measuring the complex environments that are formed and installed inside the hull of a vessel.

Engine rooms, Sounding tables, Ballast Water treatment rooms, shafts, pump rooms, steering rooms, deck areas, funnel areas, cabin rooms, the Ship bridge and others, can be captured in a few minutes, with the visual and measurable point cloud product. The billion points from which the cloud is consisted of, are the billion measurements in space, captured by the scanstations at the field of work, forming the three dimensional coloured visual outcome.

Ship Lines Extraction

Amongst the countless applications of the 3D Scanning procedure, numbers the inspection of the design implementation. The Naval Architect and Maritime Engineer may control the development site, in real time, everyday, remotely from the office, even if his actual presence is miles away.

As a mighty control implement, focuses in the advancement of the repairing, during the maintenance. It helps the alteration and the modification procedure, giving the opportunity to amend the details to fit in the everyday changing reparation site environment.

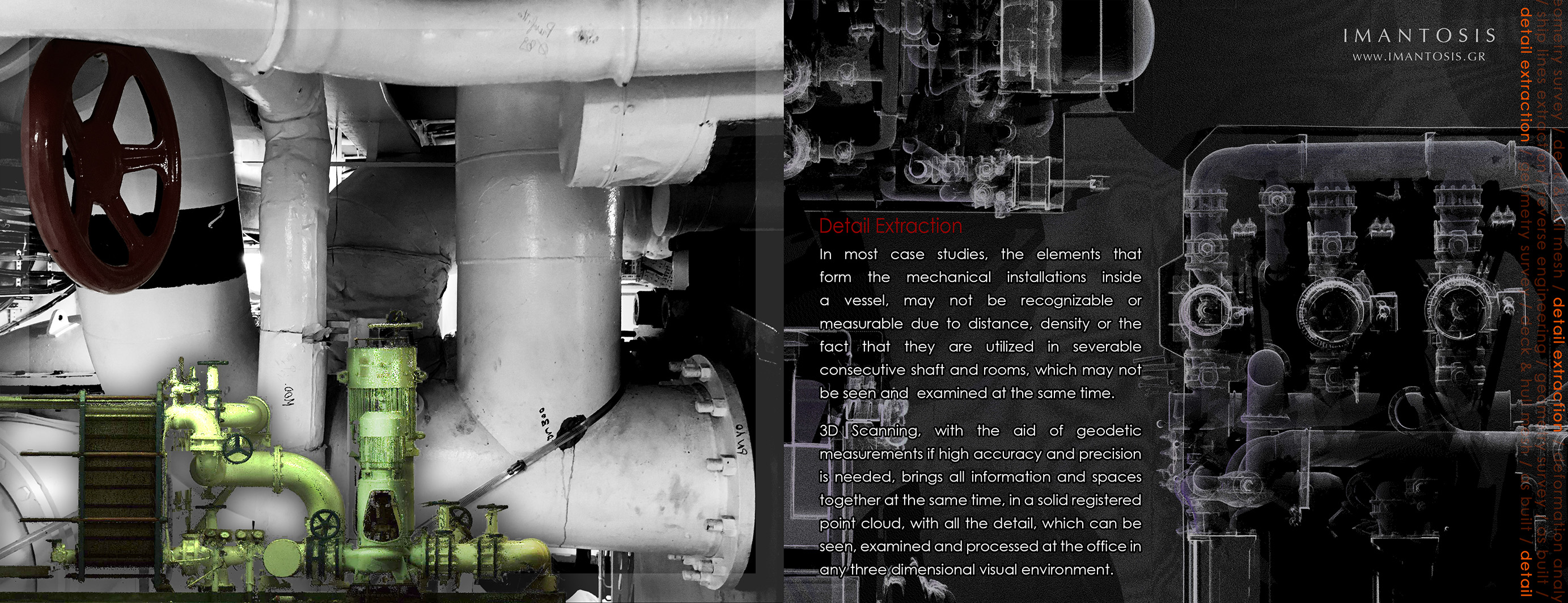

Detail Extraction

In most case studies, the elements that form the mechanical installations inside a vessel, may not be recognizable or measurable due to distance, density or the fact that they are utilized in severable consecutive shaft and rooms, which may not be seen and examined at the same time.

3D Scanning, with the aid of geodetic measurements if high accuracy and precision is needed, brings all information and spaces together at the same time, in a solid registered point cloud, with all the detail, which can be seen, examined and processed at the office in any three dimensional visual environment.

Deck & Hull Mesh

Following the 3D Laser Scanning procedure, data processing of the point cloud may lead to a three dimensional object, allowing the designer to alter the geometry of the decks, move construction beams or even ladders and other fixed equipment. Also may produce new components for the vessel, such as pools, sun decks, sun awnings and other architectural elements, with the exact accuracy to be constructed at a CNC router and be fitted to the original shape with no rework. Additionally two dimensional unfolded drawings from the three dimensional object, are amongst the common derivatives for teak deck installations and detail design.

Large Scale Deck & Hull Mesh

Handling the repairs and the maintenance of Carrier Giants, from Coastal Tankers, VLCC & ULCC, to LNG Carriers and Lube / Diesel Barges, 3D models quicken the procedures. Accurate geometry inspection of the entirety of the vessel, regardless of its size, can be accomplished with the use of graphs showing longitudinal and vertical deformations, twist, straightness and deformations from the Hogging - Sagging effect. In addition, from the 3D models, the Naval Engineer may export any volumetric measurement of the rooms in the keel line, avoiding rough approximations and trigonometric algorithms.

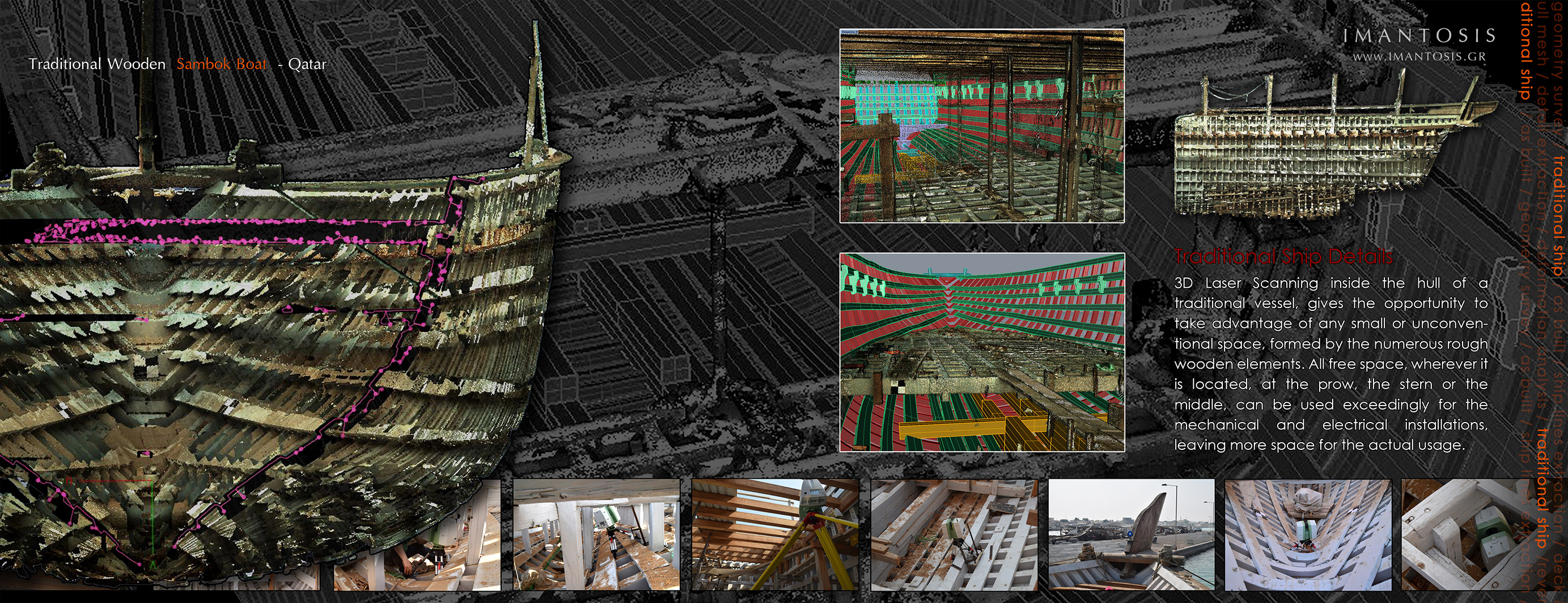

Traditional Ship Survey

One of the most difficult situations a Naval Architect Engineer can face, is the re-use of a traditional keel. With no naval drawings and not knowing the deformation conditions of the Ship, a contemporary usage, has to be placed.

3D Laser Scanning unfolds the secrets of the traditional shipbuilder, giving all the necessary gear to face and boost the reconstruction.

Traditional Ship Details

3D Laser Scanning inside the hull of a traditional vessel, gives the opportunity to take advantage of any small or unconventional space, formed by the numerous rough wooden elements. All free space, wherever it is located, at the prow, the stern or the middle, can be used exceedingly for the mechanical and electrical installations, leaving more space for the actual usage.

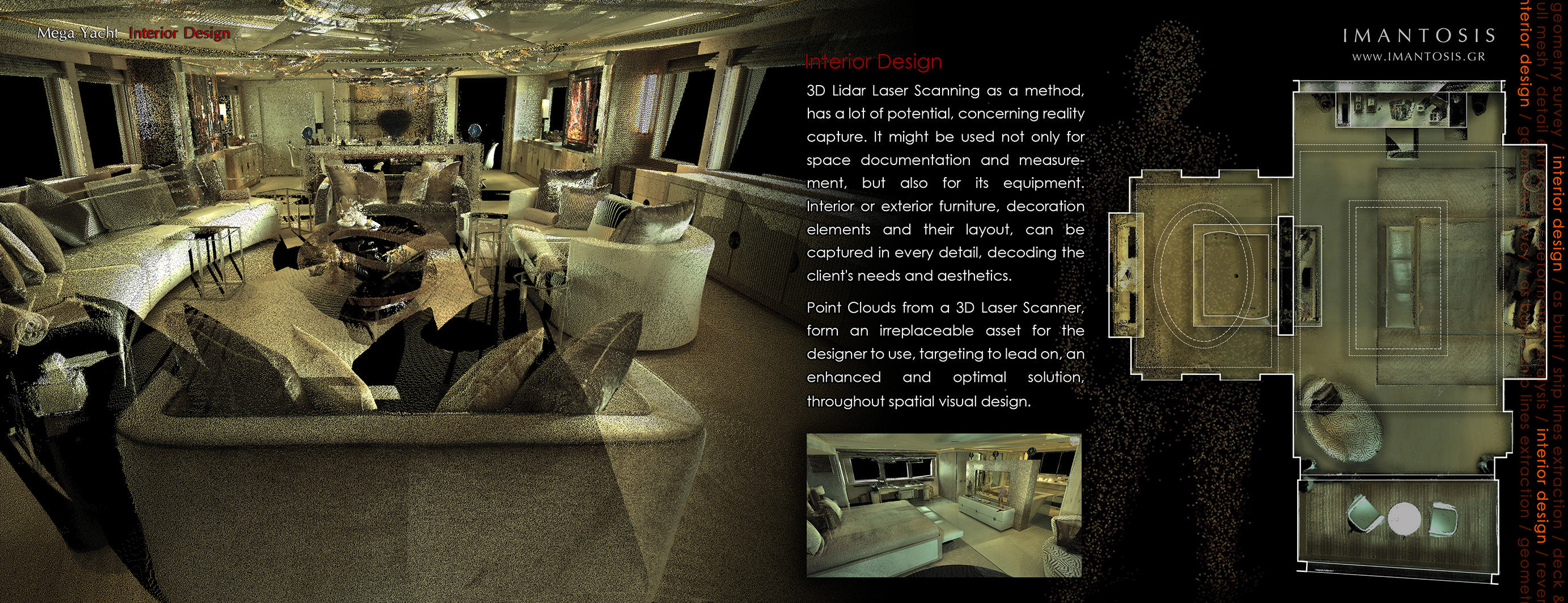

Interior Design

3D Lidar Laser Scanning as a method, has a lot of potential, concerning reality capture. It might be used not only for space documentation and measurement, but also for its equipment. Interior or exterior furniture, decoration elements and their layout, can be captured in every detail, decoding the client's needs and aesthetics.Point Clouds from a 3D Laser Scanner, form an irreplaceable asset for the designer to use, targeting to lead on, an enhanced and optimal solution, throughout spatial visual design.

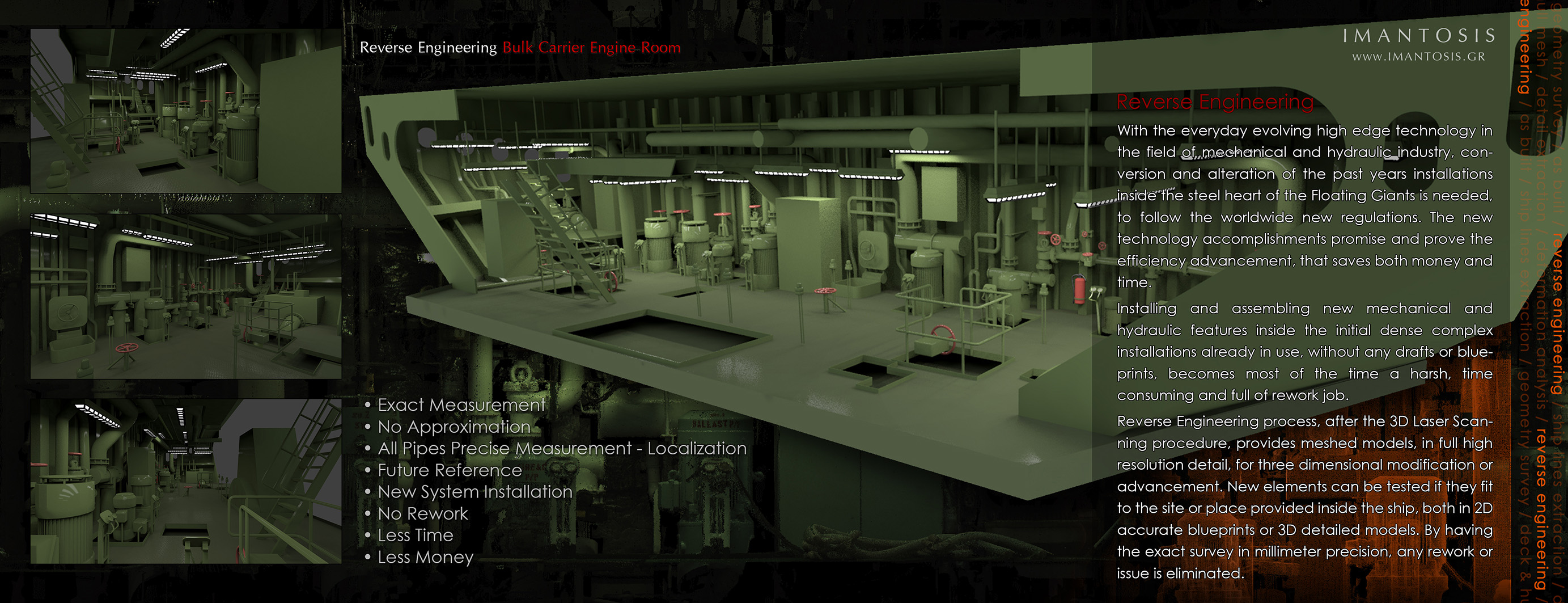

Reverse Engineering

With the everyday evolving high edge technology in the field of mechanical and hydraulic industry, conversion and alteration of the past years installations inside the steel heart of the Floating Giants is needed, to follow the worldwide new regulations. The new technology accomplishments promise and prove the efficiency advancement, that saves both money and time.Installing and assembling new mechanical and hydraulic features inside the initial dense complex installations already in use, without any drafts or blueprints, becomes most of the time a harsh, time consuming and full of rework job.

Reverse Engineering process, after the 3D Laser Scanning procedure, provides meshed models, in full high resolution detail, for three dimensional modification or advancement. New elements can be tested if they fit to the site or place provided inside the ship, both in 2D accurate blueprints or 3D detailed models. By having the exact survey in millimeter precision, any rework or issue is eliminated.

• Exact Measurement

• No Approximation

• All Pipes Precise Measurement - Localization

• Future Reference

• New System Installation

• No Rework

• Less Time

• Less Money

plus2.jpg&w=150&aoe=1)